Vessel Rotators are known by many names such as tank turning rolls, vessel welding Rotators, tank welding rotators, tank rollers and many more. Vessel rotators are welding fabrication workshop attachments that are used to keep a vessel or tank in place while rotating large cylindrical parts around a horizontal axis at a consistent and steady speed in front of a welding head. Similarly capable of rotating the vessel in steps until the needed position is reached depending on the welding job in hand.

Vessel rotators help to increase the production speed along with reduced labour cost due to less requirement of lifting or crane facilities, which additionally reduces idle time. Our vessel rotators can be used for both automatic and manual welding, which aids in the production of high-quality circumferential joints on vessels.

Use Cases

Vessel rotators can be used to perform circumferential welds in a vertical plane, longitudinal weld in horizontal plain and surfacing (cladding) or depositing by welding a filler metal of useful properties on the external or on the internal surface of a vessel.

Vessel Rotators are utilized in large-scale welding plants to increase workstation efficiency and safety.

Working Principal

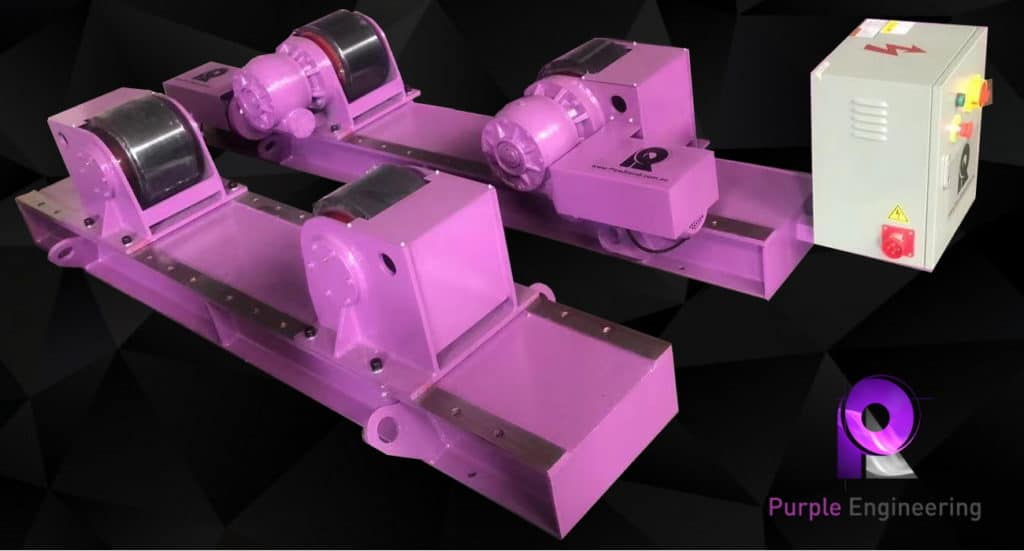

Vessel rotators are arranged in sets, including a pair of identical rolls, one of which is powered by an electric motor through a reduction gearbox while the other one is idle. Distance between rolls can be manually adjusted or more advanced self-align options are available with Purple Engineering vessel rotators. This allows accommodating vessels or tanks of different diameters mounted on the frame. Usually, a pair of such frames must be arranged at a suitable distance from one another, to safely hold the tank or the vessel to be handled.

Variants

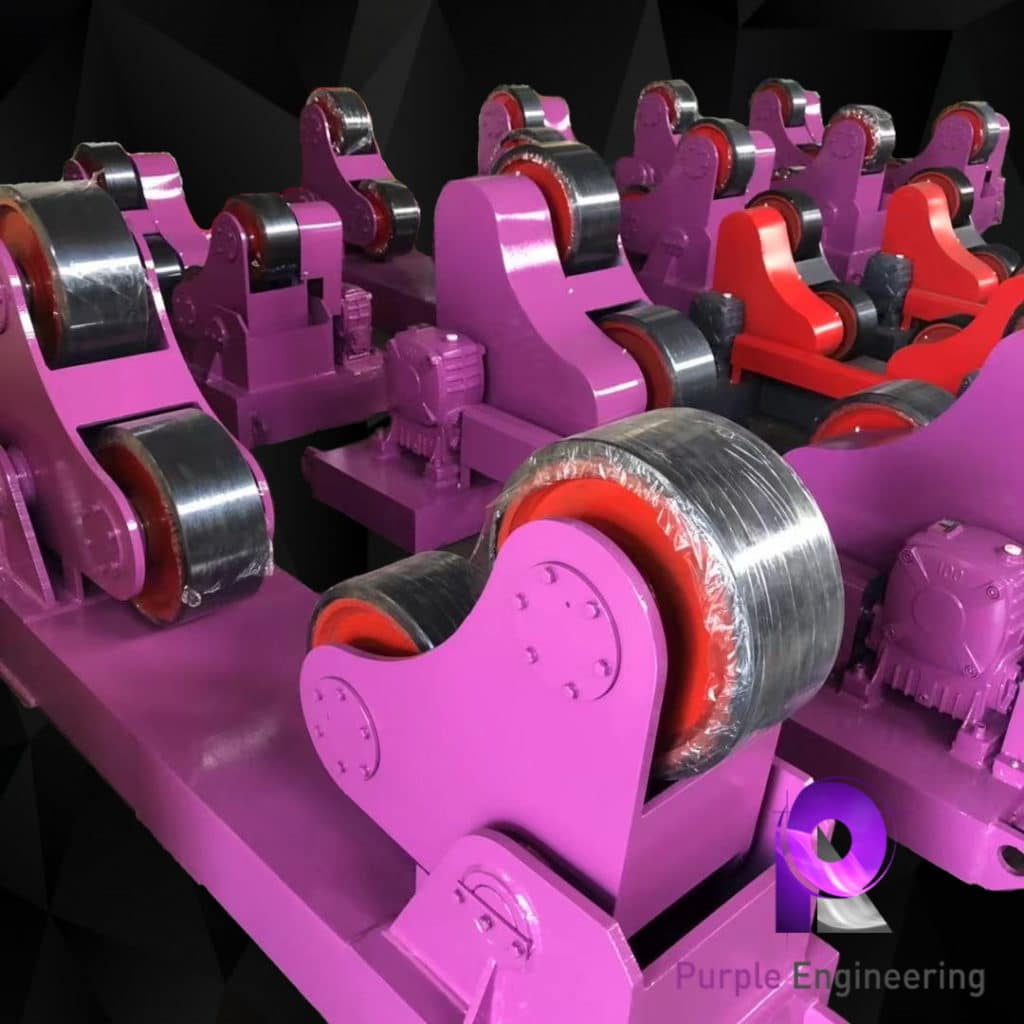

Holding capacity and diameters that can be supported are the major parameters that define the variants of rotators. Other features include the wheel and surface materials, as well as the power and surface speed offered.

In Purple Engineering we offer the best solution for your requirements,

- 5 TON Adjustable Vessel Rotator

- 10 TON Adjustable Vessel Rotator

- 15 TON Adjustable Vessel Rotator

- 20 TON Adjustable Vessel Rotator

- 5 TON Self-Aligned Vessel Rotator

- 10 TON Self-Aligned Vessel Rotator

- 15 TON Self-Aligned Vessel Rotator

- 20 TON Self-Aligned Vessel Rotator

Apart from these variants, we offer customized vessel rotator solutions up to 800 TON in Bolt-adjusting vessel rotators along with up to 300 TON in Self-adjusting vessel rotators. All our Vessel Rotators comes with TUV Load test certification which is the only TUV certified vessel rotator in Australia.

How to use

The free-turning part of the vessel rotator should be determined before beginning the welding procedure to ensure that no protrusions interfere with the motion. Also, the longitudinal weight distribution should be properly checked to prevent overloading. Special attention needs to be paid to avoid instabilities that may cause the workpiece to overturn. Minute inaccuracy in positioning may involve translation of the workpiece along its axis. Any parallel or out of square turning rolls may cause drag forces that cause the workpiece to move erratically. Welding rollers are available in steel, rubber, or polyurethane. Welding Rotators are simple positioners, but they must be kept in good working order at all times. One should approach every job and every part with care, seriously and thoroughly, possibly following a standard checklist and learning from previous experience.

WHY CHOOSE PURPLE ENGINEERING?

We're your friends in the field that genuinely care about our clients projects. We work towards establishing relationships with our clients that lasts for decades not days. That's why we always put our clients' satisfaction first.

We have a wide range of products on offer and hold stock on hand of our critical and high-volume items. This means you can find what you need when you need it.

We have a proven track record of success, and our clients are always happy with the final product. And we're always up for a challenge and love a good puzzle. If you're looking for a reliable, experienced supplier who genuinely cares about your project, look no further than Purple Engineering

YOU DIDN'T FIND THE RIGHT PRODUCT?

Purple Engineering is providing a wide range of Pipeline and Oil & Gas equipment. It is possible that we have the product you are after or know who in the market has it! Please call us and we can confirm if we have the item you are searching for.