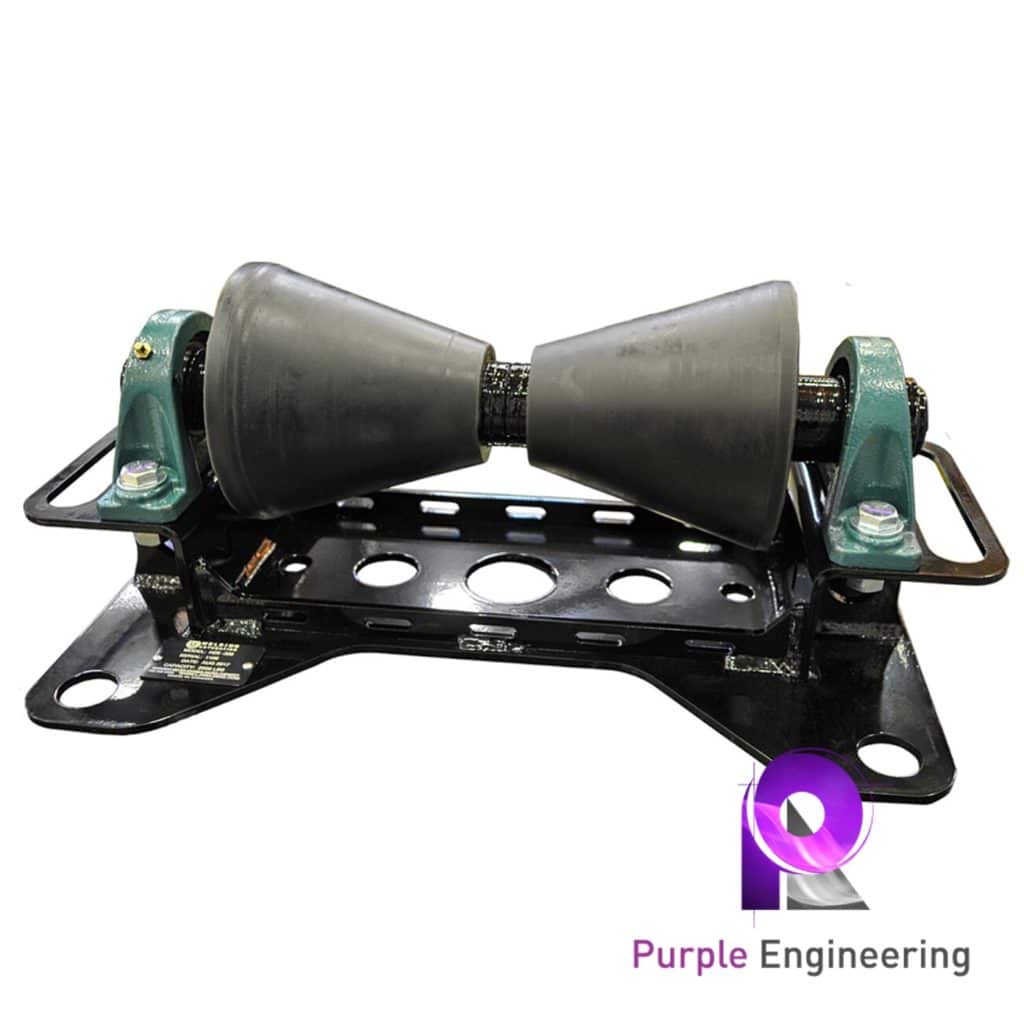

Pipeline rollers are designed to safeguard, support, and manage a pipeline segment during river and road crossings. Pipe guide rollers support to minimize drag forces of pipe-pulling through horizontally drilled or bored holes. There are varieties of Pipeline rollers with many load ratings, certifications, roller heads & roller directions.

1 Ton Pipeline Roller

The 1 Ton Pipeline Roller is also called as 1-Ton, 2–24″ OD HZ6-300. The Load Capacity is 2,000 lbs. / 1 Ton. The diameter ranges from 2″-24″. The shipping dimensions are 26¾” x 16¾” x 8½” (to top of roller) and the weight is about 90 lbs. In 1 Ton Pipeline Rollers handles are available for easy lifting and moving on-site. The roller helps to protect the exterior of the pipe (coatings/yellow jacket) during the crossing installations (i.e., river, road, crossings) and reduces drag/pulling forces substantially.

The pipe roller provides smooth and safe rolling that keeps the pipes above the ground, away from any contaminants that could cause damage to it. It makes the process of handling and rolling easier, timesaving, and reduces strain on operators. The roller keeps the job site running more efficiently which causes to increases productivity and profitability. Overall, less equipment is needed on job sites, this creates easier movement all around. Furthermore, the design allows it to execute curved pulls, and its convenient lightweight ensures that the pipeline roller can be easily lifted with chains, straps, or forks. Finally, it is designed to protect the pipe exterior and minimize drag as the pipe is pulled through horizontal drill holes.

5 Ton Pipeline Roller

The 5 Ton Pipeline Roller is also called as 5-Ton, 4–48″ OD HZM10-100. The Load Capacity is 10,000 lbs. / 5 Ton. The diameter ranges from 4″-48″. The shipping dimensions are 63″ x 34″ x 24″ (to top of roller) and the weight is about 690 lbs. In 5 Ton Pipeline Rollers, forklift pockets, and lift hooks are available for easy movement. The roller helps to protect the exterior of the pipe (coatings/yellow jacket) during the crossing installations (i.e., river, road, crossings) and reduces drag/pulling forces substantially. 5 Ton Pipeline Rollers are used to guide the tubes during installation and to center the piping accurately as it moves along the feeder cradle. Its rolling surface is having dual v-rollers, with the use of oversized roller bearings. The pipeline rollers are also utilized for maintaining pipes that convey petroleum products, crude oil, and natural gas to destinations around the world.

This roller provides a modular design that allows it to execute curved pulls, and its convenient lightweight ensures that it can be easily lifted with a chain, straps, or forks. It ensures smooth and safe rolling that keeps the pipes above the ground, away from any dirt or anything else that could cause damage to it. Apart from this, the roller is designed to protect the pipe exterior and minimize drag. The process of handling and rolling pipes is easier and it is time-saving and reduces strain on operators. It is responsible for a job site running more efficiently which increases productivity and profitability. Overall, less equipment is needed on job sites which creates easier movement all around.

10 Ton Pipeline Roller

The 10 Ton Pipeline is also called as 10-Ton, 4–48″ OD HZM10-100. The Load Capacity is 20,000 lbs. / 5 Ton. The diameter ranges from 4″-48″. The shipping dimensions are 63″ x 34″ x 24″ (to top of roller) and the weight is about 690 lbs. The Rolling Surface has consisted of dual v-roller style, moulded urethane, oversized roller bearings, and an optional horizontal roller for the small-diameter pipe. The roller Is featured with forklift pockets and lifts hooks for easy movement on Jobsite

This is designed to protect the pipe exterior and minimize drag as the pipe is pulled through horizontal drill holes. The design also allows it to execute curved pulls, and its convenient lightweight ensures that it can be easily lifted with a chain, straps, or forks. This results in smoother and safer rolling that keeps the pipes above the ground, away from any contamination that could potentially damage them. The device makes the process of handling and rolling easier, timesaving, and reduces strain on operators. It responds to a job site running more efficiently and increases productivity and profitability. In the end, it also means less equipment needed on job sites that creates easier movement for operators.

40 Ton Pipeline Roller

The 40 Ton Pipeline Roller is also called as 40-Ton, 4–72″ OD HMZ405-100. The Load Capacity is 80,000 lbs. / 40 Ton The diameter ranges from 4″-72″. The shipping dimensions are 68″ x 56″ x 33″ (to top of roller) and the weight is about 1,725 lbs. The Rolling Surface has consisted of dual v-roller style, moulded urethane, oversized roller bearings, and an optional horizontal roller for the small-diameter pipe.

The roller is featured with adjustable rollers, forklift pockets, and lift hooks for easy movement on the job site. The roller helps to protect the exterior of the pipe (coatings/yellow jacket) during the crossing installations (i.e., river, road, crossings) and reduces drag or pulling forces substantially. This is composed of a heavy design that is used to support, guide, and protect a pipeline throughout various applications that include rolling.

Apart from protecting the exterior of pipe (coatings/yellow jacket) during crossing installations (i.e., river, road, crossings), it reduces drag or pulling forces substantially. Besides that, the roller also minimizes drag as the pipe is pulled through horizontal drill holes. The design also allows it to execute curved pulls, and its convenient lightweight ensures that it can be easily lifted with a chain, straps, or forks. This results in smoother and safer rolling that keeps the pipes above the ground, away from any contamination that could potentially damage them. This makes the process of handling and rolling easier, time-saving, and reduces strain on operators. It causes the job site to run more efficiently which increases productivity and profitability. In the end, it also means less equipment required on job sites that creates easier movement for operators.

The roller is used to guide the tubes during installation and to center the piping accurately as it moves along the feeder cradle. Its rolling surface consists of an 8-roller system, using moulded oversized roller bearings. The pipe rollers are used for supporting pipes that convey petroleum products, crude oil, and natural gas to destinations around the globe.

2 Ton Multi-Directional Pipe Roller

The 2 Ton Multi-Directional Pipe Roller is also called a 2-Ton, 2–8″ OD HMZ405-100. The Load Capacity is about 4,000 lbs. / 2 Ton. The diameter ranges from 2″-8″. The footprint is 157/8″ x 9¼” x 51/8″ and the weight is about 40 lbs. Meanwhile, the Beam Clamp Flange Size Range is 6-12″ Flange Widths, up to 1″ thick.

2 Ton Multi-Directional Pipe Roller is featured with an Extra-small footprint for tight spaces.

Pipeline Rigging & Installation Roller

The Pipeline Rigging & Installation Roller is a 24-30″ utility pipe to be fitted in tight spaces on a bridge. The diameter varies from 2″-36″. Customer required bridge beam rollers use for both installation and permanent support of the various sized pipes. Load Capacity of the Pipeline Rigging & Installation Rollers can be designed in a way to meet customer requirements. Furthermore, it can be used for Offshore Pipeline Shute / Bridge Pipeline Installations

Pipeline Rigging Cradle

The Pipeline Rigging Cradles are utilized as an efficient method for maintaining and rolling pipes at the entrance of pipeline crossings. The cradle is safely supports, guides, and protects the pipe. Various cradle models are available for the pipes from 2″ to 60″ (60.3 mm – 1524 mm) in diameter.

Pipeline Rigging Cradle has the following features to ensure its optimum characteristics. On one side it handles a wide range of pipe sizes. Meanwhile, multiple polyurethane rollers are spaced equally to support the pipe evenly eliminating damage to the pipe. It is designed for quick disassembly for transit and storage purposes.

The presence of heavy-duty polyurethane rollers eliminates pipe exterior or coating damages. The Pipe can be kept back close to the ground for simpler pipe handling during installation. Pipeline Rigging Cradles are an effective method for supporting and rolling pipes at the entrance of pipeline crossings. The cradles are safely supported, guide, and protect the pipe.

The following standard models are available in the PipeStand.com.au, PRC-100: 12-24″ OD x 30,000 lbs capacity, PRC-200: 24-36″ OD x 60,000 lbs capacity, PRC-300: 36-48″ OD x 75,000 lbs capacity and the PRC-400: 48-60″ OD x 100,000 lbs capacity

WHY CHOOSE PURPLE ENGINEERING?

We're your friends in the field that genuinely care about our clients projects. We work towards establishing relationships with our clients that lasts for decades not days. That's why we always put our clients' satisfaction first.

We have a wide range of products on offer and hold stock on hand of our critical and high-volume items. This means you can find what you need when you need it.

We have a proven track record of success, and our clients are always happy with the final product. And we're always up for a challenge and love a good puzzle. If you're looking for a reliable, experienced supplier who genuinely cares about your project, look no further than Purple Engineering

YOU DIDN'T FIND THE RIGHT PRODUCT?

Purple Engineering is providing a wide range of Pipeline and Oil & Gas equipment. It is possible that we have the product you are after or know who in the market has it! Please call us and we can confirm if we have the item you are searching for.