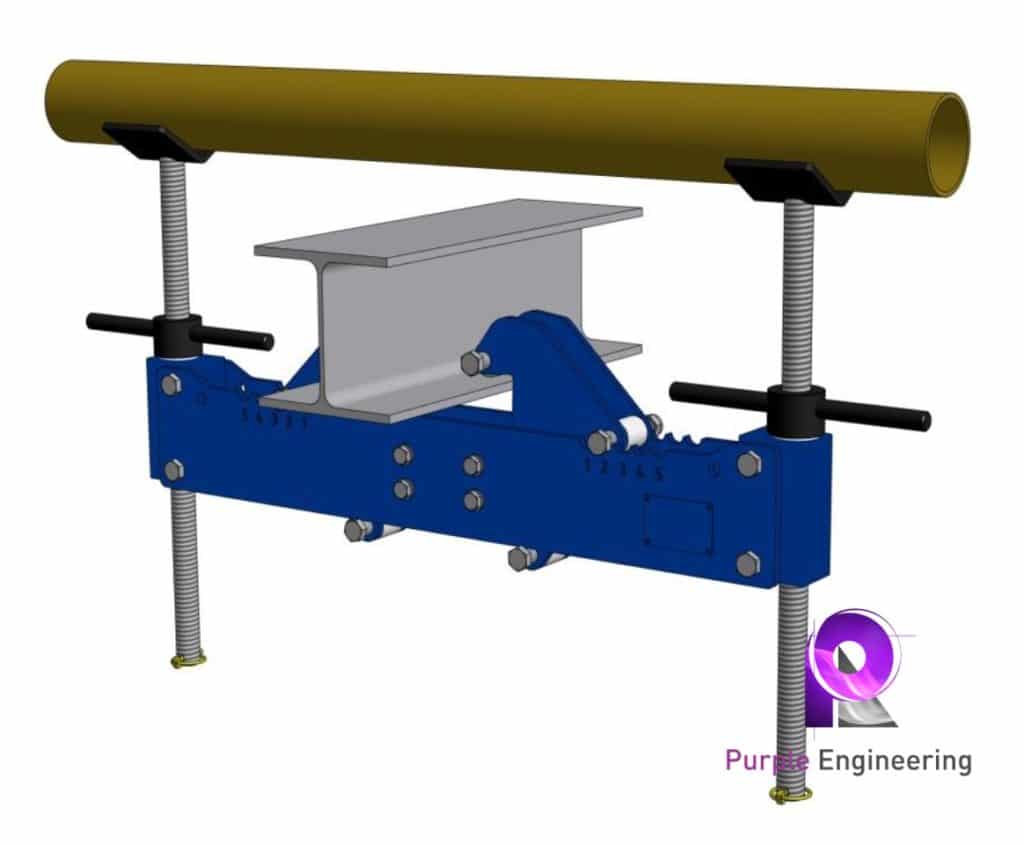

The Pipe Lifting Jack is a patented, revolutionary, simple, and yet highly cost-effective unit serving the pipe fitting industry. Engineers have developed this unit so that expensive cranes and scaffolding become unnecessary. Lifting pipes in pipe racks by means of the Pipe Lifting Jacks is very easy and safe, just by mounting them at the bottom of the beam that is helping the pipe and pressing the pipe upwards. Inspection of pipes, replacing or refurbishing of supports, and other maintenance purposes can be done in a very cheap and easy way. The Pipe Lifting Jacks are indispensable for any job where time and money want to be saved.

The base material of the Pipe Lifting Jacks is anodized high tensile aluminium. Beamwidth is about 100 to 320 mm while beam height ranges from 100mm to 450 mm. The lifting height is 470 mm minus ‘beam height’ and the capacity is 2500 kg. The operating temperature is about -40°C to 100°C and the weight is 16.4kg (body) + 4.6kg (spindle 1) + 4.6kg (spindle 2) = 25.6 kg while the dimensions are 926mm x 278mm x 120 mm.

Cost-effectiveness, time-saving, simplicity are the main benefits of using Pipe Lifting Jacks. Moreover, they are solid corrosion-resistant, multifunctional, and purely mechanical devices. The absence of hosting devices makes no periodic inspection. The Pipe Lifting Jacks gain conform acc to 2006/42/EC standard. Accessories necessary are multiple wire lengths, a handy storage case, and attachments to lift in the function of the pipeline material.

Target groups and industries of the Pipe Lifting Jacks are pipeline builders, maintenance departments, security services (fire), inspection services, (Petro)chemical industry, power plants, refineries, paper mills, bio-ethanol plants, LNG, and offshore, food, Industrial HVAC and wherever pipelines are present.

The procedure to fix the Pipe Lifting Jack is as follows. First, keep the Pipe Lifting Jack on the beam with a belt. Then hook one clamp at the beam and bring Pipe Lifting Jack horizontal. After that hook another clamp at the beam and adjust both clamps to get them as inwards as possible. Make sure that there are 9 different distances. Finally, push the pipe by turning the spindle nuts. There are a variety of Pipe Lifting Jacks available in the market.

2.5 Ton Pipe Rack Jack

The Pipe Rack Jack is a, patented, revolutionary pipe lifting tool, a simple and yet highly cost-effective unit serving the pipe fitting industry. Lifting pipes in pipe racks by means of the Pipe Rack Jack is very simple and secure, just by installing the pipe rack jack at the bottom of the beam that is supporting the pipe and pushing the pipe upwards.

The base material of the 2.5 Ton pipe rack jack is anodized high tensile aluminium. The beam height ranges from 100 mm to 320 mm while the beam width averages from 100 mm to 320 mm. The maximum allowable load is 2500 kg, and the operating temperature is between -40°C to +100°C. The minimum lifting height is 150 mm while the own weight is about 24,3 kg. The dimensions of the 2.5 Ton Pipe Rack Jack are 926 x 278 x 120 mm. The CE approved, conform acc to 2006/42/EG standard, and invented, developed, and made in Belgium.

There are accessories needed to fix the Pipe Rack Jack. The Big V is attached with a broader base, which is also lined with cellular rubber, providing optimal protection of the pipe. It is also suitable for insulated pipes. The availability of this option, the Pipe Rack Jack is fixed so that it is possible to load the spindles differently and independently. The 2.5 Ton Pipe Rack Jack can be applied to lining up and welding 2 pipes together and for sawing away a damaged part of a pipe and replacing it with a new section.

There are restrictions to be aware of when using this equipment. To avoid damaging the profile, it is necessary to take care of the difference in the load of the spindles in a way that avoids becoming too big. The maximum allowed difference in load is decided in relation to the thickness of the vertical flange of the profile.

2 Ton Pipe Lifting Jack

The 2 Ton Pipe Lifting Jack is one of the popular types that is available in the market. Pipe lifting jacks are a cost-effective way of installing pipes in tight working spaces. They are totally mechanical and do not depend on any power source for functionality. It can be applied to lift and lower pipe on or off pipe racks during installation and pipe removals. It is considered as a perfect complement to the pipe rigging rollers to avoid the need for cumbersome slings, jacks, or chain hoists to set pipe on or lift-off of rollers.

The load capacity of the 2 Ton Pipe Lifting Jack is 4,000 lbs (2-ton) and pipe diameter ranges from 0-18″ OD. The beamwidth takes an average length of 5″ – 10.5″ and the height range of 12″ to 24″. The height of the screw jack adjustable beam is (Web Height) about 8″ – 15″ and the mass of the equipment is 98 lbs and the footprint is in between 29″ x 8.5″.

750 Kg Pipe Lifting Jack

The 750 Kg Pipe Lifting Jack is another type of popular type that is available in the market. It can be applied to Pipe rigging jacks that are used to lift and lower pipe on or off pipe racks during installation and pipe removals. It is considered as a perfect complement to the pipe rigging rollers to avoid the need for cumbersome slings, jacks, or chain hoists to set pipe on or lift-off of rollers.

The load capacity of the 750 Kg Pipe Lifting Jack is 1,500 lbs (750 kg) while the pipe diameter ranges from 0-12″ OD. The beamwidth is average from 5″ – 10.5″ and the height range is between 12″ – 24″. The screw jack adjustable beam size height (Web Height) is 8″ – 15″. The mass of the equipment is 34 lbs and the footprint is about 28″ x 6.5″.

WHY CHOOSE PURPLE ENGINEERING?

We're your friends in the field that genuinely care about our clients projects. We work towards establishing relationships with our clients that lasts for decades not days. That's why we always put our clients' satisfaction first.

We have a wide range of products on offer and hold stock on hand of our critical and high-volume items. This means you can find what you need when you need it.

We have a proven track record of success, and our clients are always happy with the final product. And we're always up for a challenge and love a good puzzle. If you're looking for a reliable, experienced supplier who genuinely cares about your project, look no further than Purple Engineering

YOU DIDN'T FIND THE RIGHT PRODUCT?

Purple Engineering is providing a wide range of Pipeline and Oil & Gas equipment. It is possible that we have the product you are after or know who in the market has it! Please call us and we can confirm if we have the item you are searching for.